Cross-sectional spatial profile plots of the CT number along bullets’ short axis revealed beam hardening and photon starvation effects that depended on bullet size, shape, and orientation within the CT scanner. Internal interfaces between jacket and core could not be identified. External bullet contours could be accurately delineated. In the reference phantom, metals were classified into three groups according to their atomic number (Z): low ( Z ≤ 13 HU 30,000). Also, the effect of bullet orientation within the CT scanner was evaluated. Bullet size and shape were measured, and composition was evaluated by comparison with the metal database. Different bullets ( n = 11) were scanned in a soft tissue-mimicking phantom.

For each material, the mean CT number (HU) was measured to construct a metal database. CT images were acquired with 70–150 kVp and 200–400 mAs and were reconstructed using an extended Hounsfield unit (HU) scale (− 10,240 to + 30,710). MethodsĪ metal reference phantom was developed containing small discs of various common metals (aluminum, iron, stainless steel, copper, brass, tungsten, and lead).

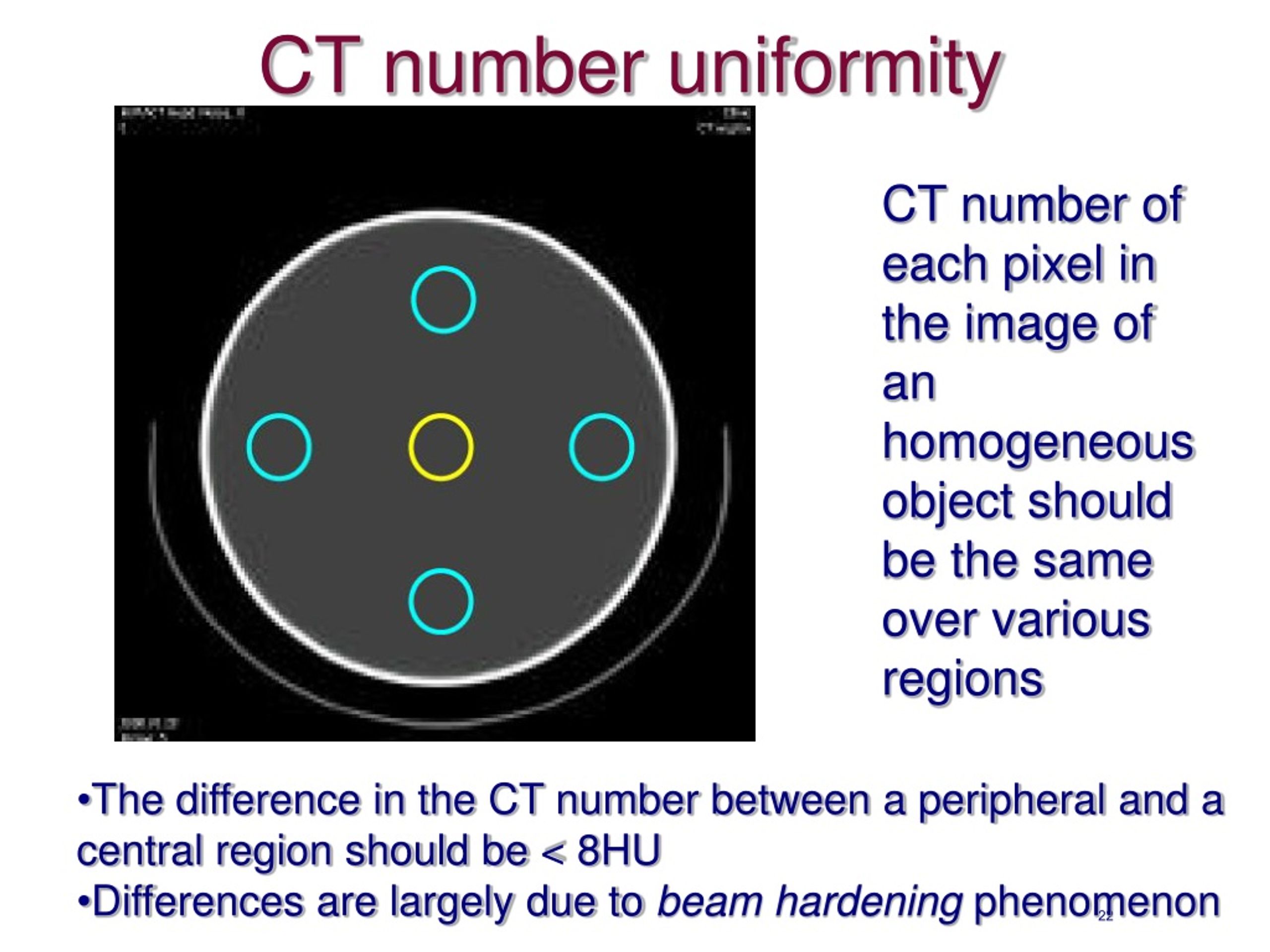

Bullet visualization with CT is challenging as the metal constituents suffer from excessive X-ray attenuation due to their high atomic number, density, and geometry. Therefore, the use of CT imaging was explored for the analysis of bullet geometry and composition. Forensic investigations could benefit from non-invasive in situ characterization of bullets.

0 kommentar(er)

0 kommentar(er)